‘How to’ change the Tankmaster body without draining your tank

In this manual, we are going to go through the process of replacing the TankMaster body without removing the union and valve from the tank.

This will allow you to change the body without having to wait for the tank to be empty. This routine is completely safe to under-go while

the appliance is connected to the tank

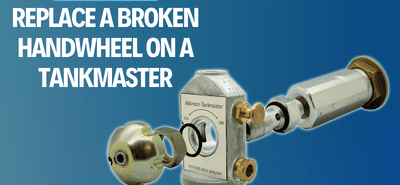

The first step would be to isolate the fuel supply from the TankMaster by rotating the handwheel clockwise until the handwheel is free spinning on the stem.

Once that has been done, manually ensure that there is no fuel passing through the valve by removing the filter bowl over a bucket.

You can then remove the E-circlip from the indentation in the stem. A flat head screwdriver may be used to assist as it can be a little tight.

Now that the handwheel has been removed, you should be presented with what you see here in image 3.

You will now need to remove the hex nut which is holding the union and valve to the body.

Once this has been removed you will now be able to pull the body away from the union and valve but more importantly, the tank.

Important: Please remember that if you have a sight gauge attached to the TankMaster, you may have a sight gauge full of oil.

If so, please remove the top clip from the tank and drain the contents of the sight gauge into a CLEAN bucket, then pour the contents of the bucket back into the tank through the observation hatch. – The contents of the gauge will not pour through the Tankmaster as the pull to read valve sits closed.

Now that the TankMaster has been removed from the union and valve, you will be left with the union and valve along with the extension (As shown in picture 5) piece connected to the tank.

The fuel supply will now be isolated until another handwheel has been introduced as the valve is spring loaded closed as a failsafe measure.

You are now ready to reverse through the steps and begin re-building the TankMaster.

Please feel free to add a small degree of copper grease to the male thread of the handwheel. Once the handwheel has been connected, please rotate it anti-clockwise until it reaches a natural stop (Opening the line) and then rotate clockwise half a turn to relieve pressure on the threads. This will prevent future seizing. View our full range of Atkinson Tankmaster Valve & Spares for a complete kit.