Tigerloop Bio Deaerator

FEATURES OF THE TIGERLOOP BIO DEAERATOR:

- Can be installed internally or externally

- Maximum operating temperature of 60ºc

- Designed for gases to be vented safely outside

- Comes complete with a wall mounting bracket

- Compatible with Bio Oil and Mineral Oil

£82.60 £99.12

- Description

- Additional information

- Technical Downloads

- FAQ's

- Reviews (0)

Description

Description

TIGERLOOP BIO DEAERATOR

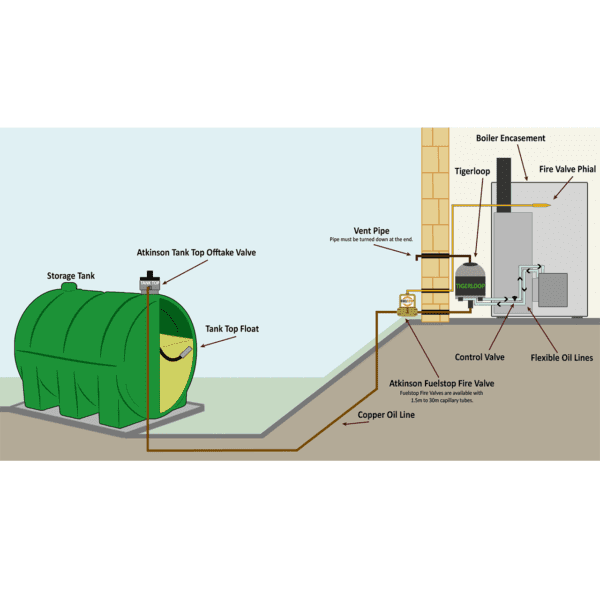

A de-aerator with all the benefits of a Tigerloop Original that can be fitted internally. With the addition of a simple to fit 10mm vent pipe the removed air can be vented safely to the outside, ensuring only pure oil is passed through to the burner. Compatible with Bio Oil and Mineral Oil (made to standard). Optional fitting kit available.

The Tigerloop Bio model is constructed externally of metal materials making it suitable for both indoor and outdoor installation in the UK & IE. The Tigerloop automatically and continuously de-aerates the fuel by venting to the atmosphere. This is the only way to prevent air or gas bubbles, which form during suction of oil from the tank, from entering the burner. This proven method of de-aeration ensures the best possible efficiency for the heating system.

A Tigerloop makes a one-pipe system possible for all types of oil heating installations helping to ensure environmental safety, cost effectiveness and reliability.

EFFECTIVE DEAERATION:

In an oil heating system using a Tigerloop, all oil passes through the automatic oil de-aerator, which effectively removes all gas/air bubbles from the system. This eliminates oil pump and nozzle problems associated with gas/air in the oil.

OWN TWO-PIPE CIRCULATION:

An oil pump delivers the same amount of oil irrespective of what is actually needed for combustion. In the case of a normal domestic burner, only 5 % of the delivered oil is actually burned in combustion. The remaining 95% is transported by a two-pipe system back to the oil tank. With a Tigerloop automatic oil de-aerator no oil needs to be transported back to the tank. The oil that is not burned in combustion is lead back to the Tigerloop where it is de-aerated again and again automatically. For this reason only the amount of oil to be burned in combustion is sucked from the oil tank.

PRE-HEATED OIL:

A one-pipe system with Tigerloop increases the oil pump capacity. Moreover, the oil is actually preheated to at least room temperature as friction in the oil pump generates heat. This eliminates problems with cold oil giving cleaner combustion and reduced oil consumption.

MINIMUM DIRT/SLUDGE:

The oil flow in a one-pipe system is minimal due to the fact that only the amount of oil burned needs to be drawn up from the tank. For this reason very little dirt/sludge is transported from the oil tank. This reduces the risk for clogged oil filters and burner nozzles. Filtration is more effective, soot build up is reduced and filter life is extended.

The Tigerloop Bio Deaerator is only one in the range of Tigerloop Deaerators please see the rest of the range here – Tigerloop Deaerators

Additional information

Additional information

| Weight | 1 kg |

|---|---|

| Nozzle Capacity | 110lph |

| Return Flow Rate | 120lph |

| Max Flow Rate | 230lph |

| Max Deaerating Capacity | 8lph |

| Max Operating Temp | 60°C |

| Max Pressure | -0.5 to +0.6 Bar |

| Connection sizes | All fittings 1/4" BSP |

Technical Downloads

FAQ's

Q. Why does gas build up in the oil line?

A. Gas will automatically be released from the oil when pressure in the oil line falls below the atmospheric pressure resulting in a vacuum (negative pressure). The quality, temperature and viscosity of the oil will also play a determining role in the amount of gas released. The higher the vacuum the more gas that will be released.

Q. When is there a vacuum (negative pressure) in the oil line?

A. When oil must be drawn up from a tank lying below the level of the oil pump gas will be released. The higher the oil is lifted, the more gas that is released. Gas is also released when friction in long oil lines causes a vacuum (negative pressure) to build in the oil line. The higher the friction, the more gas that will be released.

Q. Why do pockets of air/gas form in oil lines?

A. If the dimension of the feed line is too large (too coarse for needed oil flow), gas pockets will develop as the siphon effect is lost.

Q. How does air enter an oil feed line?

A. Air will enter the system if the feed line is not 100% tight in all connections or if the tank is run to empty.

Reviews

There are no reviews yet.