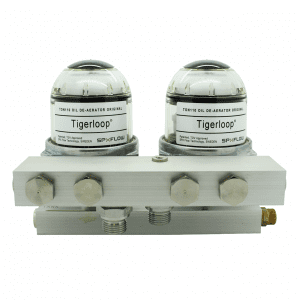

Deaerators

Such as the renowned Tigerloops, play a vital role in optimising oil heating systems. These devices are designed to remove air and gases from the fuel oil, ensuring a more efficient and reliable operation.

Tigerloops work by utilising a combination of principles. Firstly, they incorporate a vacuum-based system that creates a low-pressure zone, drawing air and gases out of the oil supply line. Secondly, Tigerloops employ a deaeration chamber which allows the separated air and fuel to vent, while the pure, deaerated fuel flows through. This results in a cleaner, air-free oil stream that is essential for smooth and efficient combustion in oil heating systems.

The importance of deaerators like Tigerloops in oil heating systems cannot be overstated. Here’s why they are crucial: 1. Improved Efficiency: Air and gases in the fuel can disrupt the combustion process, leading to inefficient and incomplete burning of oil. De-aerators ensure that only pure fuel enters the burner, maximizing energy output and reducing waste. 2. Enhanced Reliability: By preventing airlocks and blockages in the oil supply line, Tigerloops contribute to the overall reliability of the heating system. An installed also Tigerloop aids the boiler pump to pull and lift fuel from the storage tank. This reduces the likelihood of system breakdowns and costly repairs. 3. Environmental Benefits: Efficient combustion driven by de-aerated fuel results in reduced emissions, making oil heating systems more environmentally friendly. 4. Prolonged Equipment Life: Deaerators help protect critical components of the heating system, such as burners and nozzles, from wear and damage caused by impurities in the fuel. 5. Simplified Installation: Tigerloops are known for their easy installation and minimal maintenance requirements, making them a cost-effective addition to oil heating systems. In conclusion, deaerators like Tigerloops are indispensable for oil heating systems. They work to ensure clean, air-free fuel delivery, leading to improved efficiency, reliability, and environmental performance. Their role in prolonging equipment life and ease of installation make them a valuable asset in the world of oil heating.

- Anti Siphon Valves, Deaerators, Oil Heating Equipment, Oil Tank Accessories, Sale Items

Tank Top & Tigerloop Pack

From £113.59 £136.31